BEECH

veneer

about

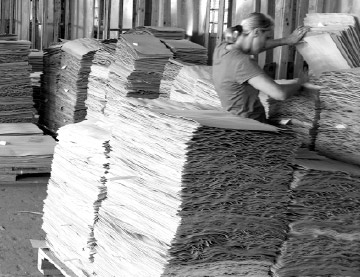

DYHA v.d. cooperative production was founded on June 1950 as a wood processing factory. The production of rotary cut and sliced veneer for molded plywood components and furniture productions started in 1970. DYHA TIROLA s.r.o., as a Limited Liability Company was established in 1997 and has continued in production of high quality and certified rotary cut beech veneer, only. Our production is certified by FSC100%, PEFC, and IPPC. Our valued customers are Top furniture producers located all around the world, mostly in Scandinavia, Benelux, UK and Japan.

history

1950

General Assembly meeting of the Wood-processing People’s Association was held on 30.06.1950 on premises of Slovak Trade Union Secretariat in Moldava nad Bodvou. The production scope consisted of wood logging, logs purchasing, wood processing, products sales and other wood works. Total sales in 1950 was 750,000 Crowns (25K EUR), with help of 24 employees.

1970

1997

After the Velvet Revolution in Czechoslovakia in 1989 when the communist regime collapsed, started a new era of transformation production companies from government controlled entities into the private companies. Many companies did not survived this difficult transformation process and got into a complicated production and financial situation.

New company DYHA TIROLA Ltd. was established in 1997 as a family owned company and took over all activities of the Wood-processing Association DYHA v.d. Owners and management of DYHA TIROLA Ltd. sold all activities and properties not linked to the veneer production and focused exclusively on the production of rotary cut beech veneer and remain with this type of production to these days.

2020

Today, our company is one of leaders in production of certified beech veneer on Scandinavian and Japanese furniture market. We provide tailor made solutions for our valued clients, with just in time de liveries to any place on the planet. Sizes, quality, moisture, thickness, volume and production lead time, that’s all we always adjust to the needs of each and every client. Our veneer is precisely controlled to meet all high quality requirements of TOP furniture producers. FSC, PEFC, IPPC certifications is a matter of course. We currently process over 8.000 m3 of beech logs annually, with 55 employees in two-shifts operation and turnover is over 2 mil. EUR.

sources

certificates

FSC

As the leader in sustainable forestry, FSC® is trusted by NGOs, businesses, and consumers worldwide to protect healthy, resilient forests for all, forever. The FSC label provides a credible link between responsible production and consumption of forest products, enabling consumers and businesses to make purchasing decisions that benefit people and the environment as well as providing ongoing business value. Our FSC100% certificate ID: SGSCH-COC-002030.

PEFC

PEFC is the world’s largest forest certification system. The credible standards seek to transform the way forests are managed globally – and locally - to ensure that all of us can enjoy the environmental, social and economic benefits that forests offer. PEFC works throughout the entire forest supply chain to promote good practice in the forest and to ensure that timber and non-timber forest products are produced with respect for the highest ecological, social and ethical standards. Our PEFC certificate ID: SGSCH-PEFC-COC-210004.

IPPC

IPPC - the International Plant Protection Convention - is an international agreement on plant health with 173 current signatories. It aims to protect cultivated and wild plants by preventing the introduction and spread of pests. The Secretariat of the IPPC is provided by the Food and Agriculture Organization of the United Nations. Our IPPC certificate ID: SK - 2439

veneer production

our team and our business

We supply our valued customers in following countries:

- Belgium

- Denmark

- France

- Holland

- Hungary

- Japan

- Latvia

- Malaysia

- Norway

- Poland

- Sweden

- Thailand

- Turkey

- United Kingdom